压送辊

(Nip roller take-up)

序号 | 胶辊名称 | 推荐材质(或牌号) | 硬度 | 性能要求 | 应用行业或作用 |

1

| 电晕放电处理胶辊 Corona roller | SI | 70~80 | 耐臭氧性、耐20万伏高压 Ozone Resistance and 200,000 Volt High Pressure Resistance | 增加薄膜表面粗糙度 Increasing Surface Roughness of Thin Films |

2 | 电晕压辊 Corona roller | EPDM | 50~70 | 耐溶剂,耐老化性 Solvent resistance, aging resistance | |

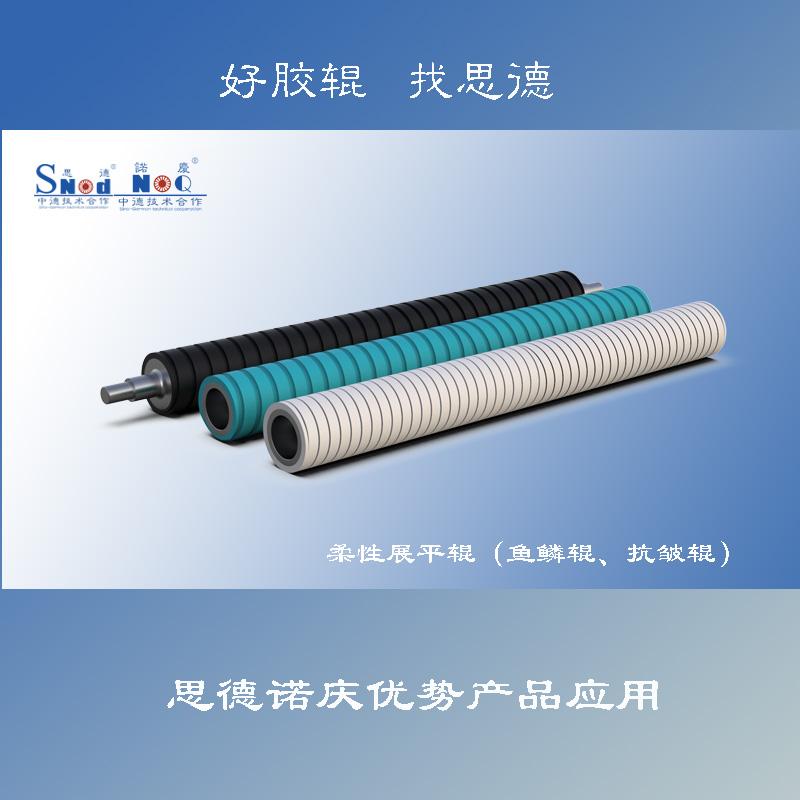

3 | 纵向拉伸(MDO)压辊 Longitudinal drawing roller | SI | 65~80 | 耐溫、耐磨 Temperature Resistance and Wear Resistance | 薄膜片材的纵向牵伸 Longitudinal Drawing of Thin Film Sheets |

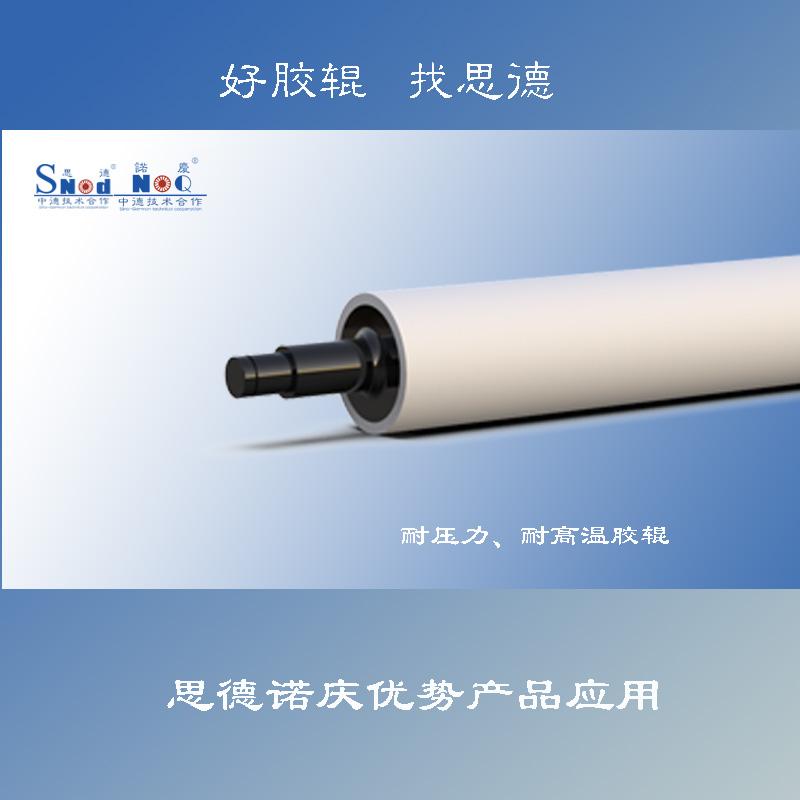

4 | 分切压辊 Cutting roller | HNBR、 PU、CSM

| 60~80 | 耐磨、耐压、抗老化 Wear Resistance, Pressure Resistance and Aging Resistance | 为薄膜分切提供压力辅助 Pressure assistance for thin film slicing |

5 | 液硅防粘辊 Liquid silicone anti-sticking roller | SI | 20~60 | 低表面能 Low Surface Energy | PP、PE、PVA、PU、PET等成膜(淋膜、流延、压延)涂布工艺 Film-forming (spraying, casting and calendering) coating process of PP, PE, PVA, PU and PET |

6 | 液硅防粘加砂辊 Liquid Silicon Anti-sticking Sand Roller | SI | 40~80 | 低表面能、防粘性好,剥离性好 Low surface energy, good anti-stickiness, good peeling | 薄膜涂布 film coating |

7 | 耐高温复合橡胶辊 High Temperature Resistant Composite Rubber Roller | SI | 70~85 | 耐高温、耐氧化 High temperature and oxidation resistance | 多层复合材料复合生产工艺 Multilayer Composite Production Technology |

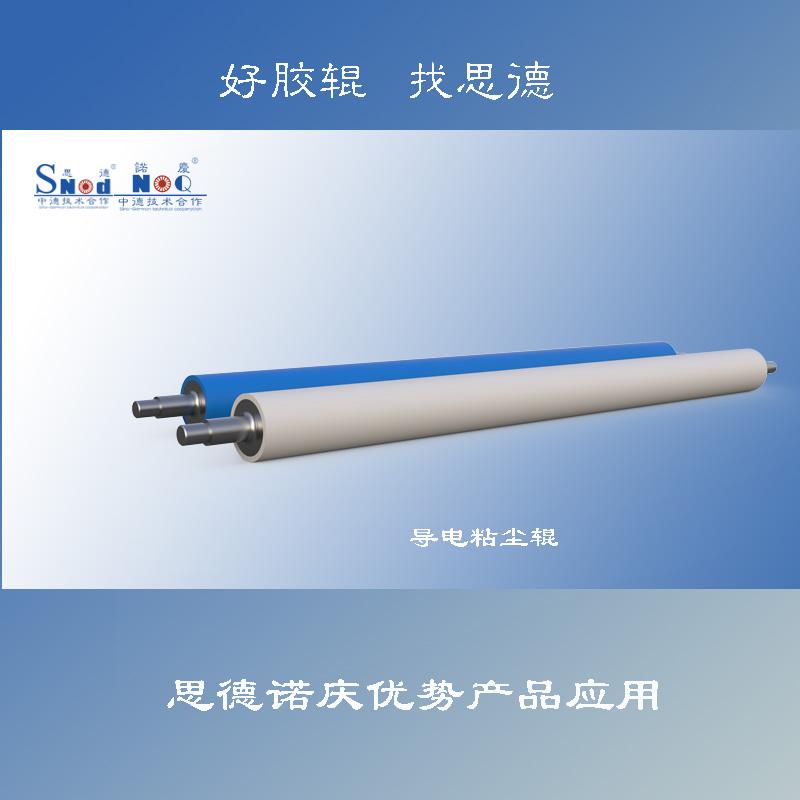

8 | 粘尘辊 Sticky roller | SI | 20~50 | 粘着性、耐热性、耐久性。分中、高、低粘度 Adhesion, heat resistance and durability. Medium, High and Low Viscosities | 有效去除材料表面杂质、降低损耗。按不同性能,产品分低粘辊、中粘辊、高粘辊、防静电辊、导电辊、清洁辊。 Effective removal of material surface impurities, reduce wear and tear. According to different properties, the products are divided into low stick roll, medium stick roll, high stick roll, anti-static roll, conductive roll and cleaning roll. |

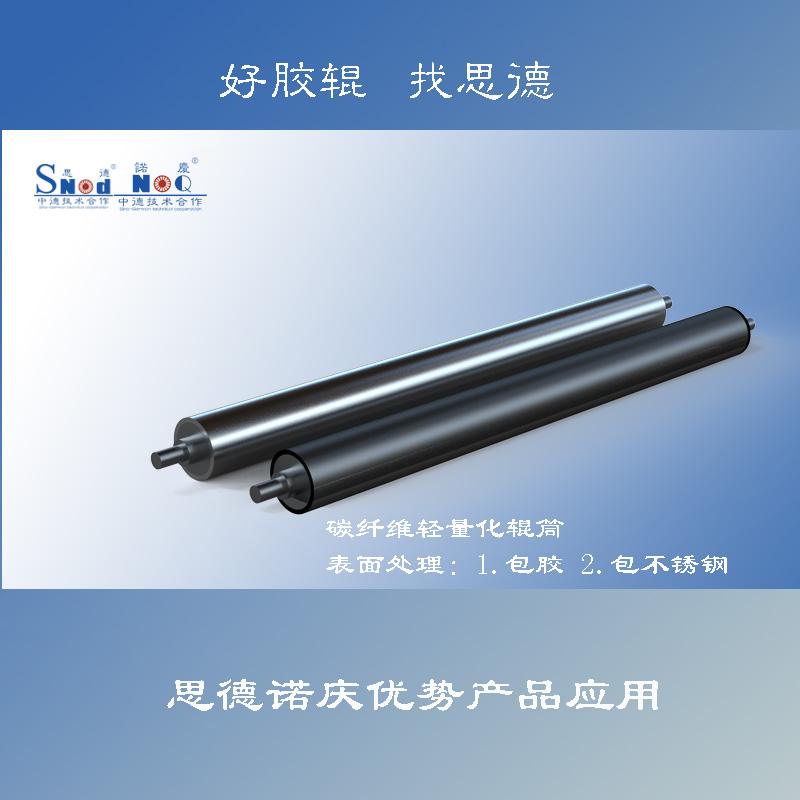

9 | 输送橡胶辊(导辊) Conveyor Rubber Roller (Guide Roller) | 30~70 | 耐磨损性、耐臭氧性 Wear resistance and ozone resistance | ||

10 | 压送辊( Nip roller take-up) | 天然橡胶、NBR Natural Rubber, NBR | 30~70 | 耐磨损性、耐臭氧性 Wear resistance and ozone resistance | |

11 | 流延橡胶辊 Casting Rubber Roller | RTV | 40~80 | 耐磨损性、低摩擦系数 Wear Resistance and Low Friction Coefficient 耐臭氧性 Ozone tolerance | PE片板膜材料 PE sheet and membrane materials |

硬度为常用行业推荐参数,可按用户要求提供Shore A 20~95°胶层硬度定制。 Hardness is the recommended parameter in common industry. Shore A 20-95 degree hardness can be customized according to user's requirements. | |||||

简体中文

简体中文 繁體中文

繁體中文